Containment Description:

The Polyvinyl and Barrier Boom Containment Systems for hydrocarbon filtration allows storm water to flow freely through the Barrier Boom side walls while capturing hydrocarbons. In the event of a large spill, the side walls completely solidify and contain the hydrocarbon, keeping it from escaping.

Containment Applications:

• Secondary Containment for:

- Substations

- Tank farms

- Wind farms

- Fueling stations

- Oilfield Applications

- And many more!

Containment Specifications:

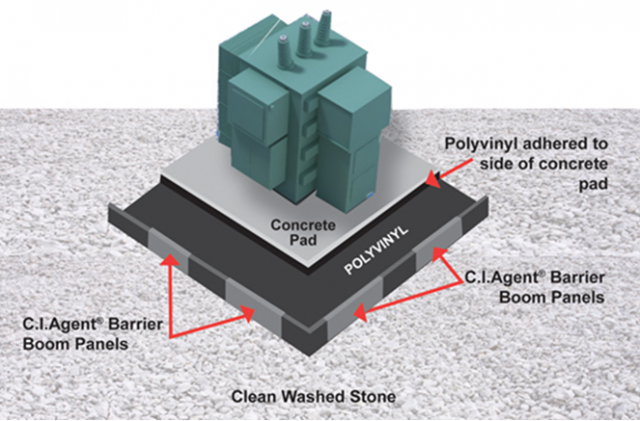

• The base of the system is made of 22oz or 40oz Polyvinyl with pre-formed corners. The side walls are made with Barrier Booms. The booms are constructed from non-woven geo-textile material filled with our proprietary blend of food-grade polymers that encapsulate hydrocarbons turning them into a solid

• Water flow rate: Minimum 3GPM per square foot of material with one foot head pressure

• Hydrocarbon flow rate: 0GPM (100%+containment)

• Service life of installed product: Life of the equipment it protects

Containment Benefits:

• A bury and forget application

• Cost-effective solution for Secondary Spill Containment

• Custom made for site specific application

• Can be installed in as little as two days (depending on size of installation)

• Will not drip or leech out

• Turns hydrocarbons into solids upon contact while water can flow freely through the side walls but hydrocarbons will never flow through the side walls of the barrier. We guarantee it with a $2 million environmental insurance on each site we complete

Polyvinyl and Barrier Boom

Containment System

What a Polyvinyle and Barrier Boom System

may look like

Proud Supplier of

Barrier Boom sidewalls staked in place and flap positioned under vinyl.

The finishing job with clean stone protecting the Polyvinyl Blanket and Barrier Boom.

Barrier Boom with vinyl liner preparing the site for install with vinyl in position.